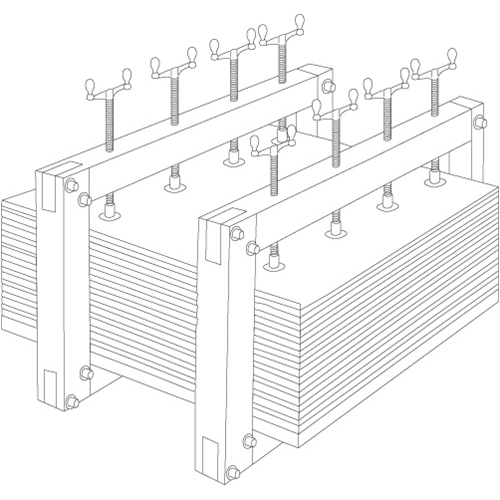

OT, but related, anyone used anything like these for 'non-vacuum' veneering?

Or, tried using a Fox style bending rig to veneer sides?

CrowDuck

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Has Anyone Built the Veneer Press From .. http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=6204 |

Page 1 of 1 |

| Author: | Brock Poling [ Mon Apr 17, 2006 5:14 am ] |

| Post subject: | |

Has anyone built the veneer press they spec out in the Joe Woodworker web site? I bought all the stuff I need and I am gearing up to make this, but I have a question and thought I would pose it here first. I am thinking about the sizes of the main reservoir tanks and the sub-reservoir chamber. My question is, what effect would it have to make them bigger? It seems obvious that the pump will cycle less, but I wonder what the trade off for that is? Will it take longer to evacuate the system and pull the clamps down? Any thoughts from you engineering types would be appreciated. I bought that GAST 5.5 CFM pump they highlight on their web site. |

|

| Author: | Pwoolson [ Mon Apr 17, 2006 5:27 am ] |

| Post subject: | |

Brock, someplace on that site Joe talks about that very topic. Though finding anything quickly on it is a bit cumbersome. Basically if you go bigger, yes, evacuation will take longer. His theory was that cycling would be less frequent but would take longer. When he indeed did it, he found that cycling was exactly the same but it still took longer to evacuate. Reason being that you are dealing with pressure and not volume. 5"HG is the same in a small container as it is in a larger container. So the vacuum switch will kick on at the same rate. But with a large container it will take longer to evacuate it out. I have two 4" x 24" reservoirs and one 3" x 24" sub. The sub is very important as the Mac valve won't have anything behind it to release if you don't use that. Found that out the hard way. Let me know if you have any other questions. P |

|

| Author: | John Watkins [ Mon Apr 17, 2006 5:52 am ] |

| Post subject: | |

I can see the point behind the resevoir for clamping purposes, but for veneering why not just use the pump directly? Mine comes on every 15 minutes for about 10 seconds at 25" HG with the bag, but runs constantly when clamping. |

|

| Author: | Brock Poling [ Mon Apr 17, 2006 6:49 am ] |

| Post subject: | |

I am using it primarily for clamping, and only occassionally for veneering. Paul to your point... that is exactly what I was interested in. The switch kicks the pump back on when it notices a 4" variance so I was unsure if a larger tank created any gains or not. Plus if I am using hide glue in my press pulling it to a full vacuum quickly is somewhat desirable. |

|

| Author: | KevinA [ Mon Apr 17, 2006 7:02 am ] |

| Post subject: | |

Brock, I built the unit just recently. I used an old Craftsman pressure tank as the main reservoir (significantly larger than the pvc tanks Joe specs in his plans) and a 3" pvc tank as the sub-reservoir. As I understand things, the only reason you need the sub-reservoir is if your vacuum pump won't restart under full vaccum (some will, but many won't). If your pump will start under full vacumm, you can eliminate the sub-reservoir and just hook up the MAC directly to the main reservoir. As for the issue of main tank size, I generally evacuate the main tank before I am ready to clamp. Then, when the valve is opened, the clamp evacuates into the main tank fairly rapidly. It seems to me the larger tank effects this pre-charge more effectvely than smaller tanks, but I can't make the comparison myself. Beyond that, I don't think the tank size has any effect on cycle times. Good luck with the build. Kevin |

|

| Author: | Pwoolson [ Mon Apr 17, 2006 7:36 am ] |

| Post subject: | |

Brock, Kevin is right about the subreservoir. It's only needed if the pump won't start up under full vacuum. You pump indeed won't start back up so you'll need it as well as the mac valve which evacuates the pressure between the main tank and the pump. I spent way too much time talking to Joe about all this so if you need any help, I'm happy to lend a hand. |

|

| Author: | Brock Poling [ Mon Apr 17, 2006 7:52 am ] |

| Post subject: | |

So... would you just build the system has he has it spec'd out with respect to the sizes of the tanks? |

|

| Author: | crowduck [ Mon Apr 17, 2006 7:53 am ] |

| Post subject: | |

OT, but related, anyone used anything like these for 'non-vacuum' veneering? Or, tried using a Fox style bending rig to veneer sides? CrowDuck

|

|

| Author: | Brock Poling [ Mon Apr 17, 2006 7:54 am ] |

| Post subject: | |

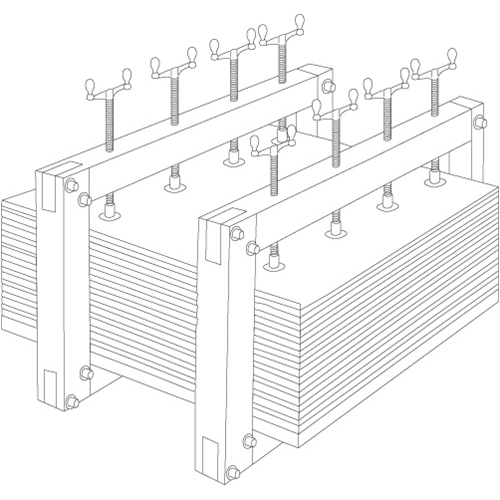

John Hall used to sell something similar to that except it had a plate that presses down and one large screw. I have used it for small veneer jobs and it works fine. I don't know if he still makes them or not. I haven't seen him offer one in years. |

|

| Author: | crowduck [ Mon Apr 17, 2006 7:59 am ] |

| Post subject: | |

Brock, Here's what you're talking about, from Grizzly, I think it's about $56. CrowDuck

|

|

| Author: | Brock Poling [ Mon Apr 17, 2006 9:13 am ] |

| Post subject: | |

Not exactly but it is similar. |

|

| Author: | Scott McKee [ Tue Apr 18, 2006 8:34 am ] |

| Post subject: | |

Chris, I once built a press like the one in your lower picture. I bolted sustantial pieces of angle iron to the cross members to beef them up but still had the screws going through the wood peices rather than the steel. Hey, I'm a woodworker, not a metalworker. Over time, the hard maple cross members broke despite the reinforcement. Were I to do it again, I'd take the time to build the frame out of heavy steel. Those veneer proess screws exert a lot of force. I'm pretty sure the press in your drawing wouldn't last too long. Vacuum bagging is so much easier. Not to be overlooked in a small shop is the fact that you can roll the bag up when not in use. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|